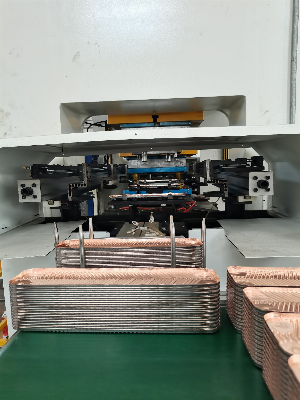

The Brazed plate heat exchanger,

assembled with two end plates and connections, is vacuum brazed at

extremely high temperatures providing a permanently sealed

heat exchanger. The final result is a strong and compact plate

heat exchanger with extremely high heat transmissions. The high

heat transmission comes from the main pattern which is designed to

create turbulent flow.Application1. Refrigeration: used as

a condenser and evaporator.2. HVAC: intermediate heat

exchangers used in conjunction with boilers, intermediate heat

exchangers in high-rise buildings, etc.3. Chemical industry: soda

ash industry, synthetic ammonia, alcohol fermentation, resin

synthesis cooling, etc.4. Metallurgical industry: aluminate mother

liquor heating or cooling, steel-making process cooling, etc.5.

Machinery industry: various quenching fluid cooling, reducer

lubricating oil cooling, etc.6. Power industry: high-voltage

transformer oil cooling, generator bearing oil cooling, etc.7.

Paper industry: heat recovery of the bleaching process, heating of

washing liquid, etc.8. Textile industry: cooling of the aqueous

solution of viscose silk alkali, cooling of boiling nitrocellulose,

etc.9. Food industry: fruit juice sterilization and cooling, animal

and vegetable oil heating and cooling, etc.10. Grease process:

soap-based drying at atmospheric pressure, heating or cooling

various process liquids.11. Centralized heating: heating the waste

heat area of a thermal power plant, heating bath water.12.

Others: petroleum, medicine, ships, seawater desalination,

geothermal utilization. Standard Materials:Flow plates and

connections in stainless steel . End plates in stainless

steel. Brazing material is pure copper. Working pressure

/Temperature:The units are constructed for max.Working

pressure/temperature 45Bar/-195°C-180°CAdditional

Equipment:Insulation.Floor mounting feet.Connection unions for

welding on pipes.In AISI 316 or ST.52-3.Recommended

Applications:1>.Refrigeration area2>.Air conditioning3>.

The HVAC area4>.Solar heating5>.Oil units6>.Heat

recovery 7>. Engine cooling and other industrial

tasks.Certificate: ISO9001:2008, CE, SGS, TUV, Q&A1. Q:

How long can we deliver goods?A: It would be 15-25 days after

payment and drawing sketch confirmed2. Q: Can your company supply

an after-sales warranty?A: Yes, we can supply 1-year after-sales

warranty against B/L date.3. Q: What payment terms can you

accept?A: We can accept L/C, T/T, etc.4. Q: Can you accept

customized order?A: Yes, we accept, we have a very

professional technical group who can design the special products

according to your basic parameter/ data sheet/ drawings or

sample.5. Q: Do you have your own factory or just you are

a trading company?A: We are the direct factory group, one is

in Guangzhou City, Guangdong Province, another is in Huanggang

City, Hubei Province.6. Q: Is OEM order acceptable to your

company?A: Yes, OEM is Welcomed.7. Q: What kind of equipment used

for manufacturing process?A: A series of high-tech equipment used

in the process of manufacture, including special

hydraulic machine for plate heat exchanger, CNC automatic

cutting machine, automatic wheat arc welding machine,

automatic plasma welding machine, CNC plate winding machine,

shearing machine and etc. 8. Q: What

are certificates and soft power used in

manufacturing process?A: Tranp has obtained ISO9001

certification, CE certification, standardized enterprise

certification and various utility model patent certificates, with

professional engineering and technical personnel engaged in the

design of heat exchange equipment, thermal system and

environmental recovery system. We will help customers to

qualify CE certificates or other foreign certificates in different

area all over the word.9 .Q: What material and

standards used for products?A: All the products are

manufactured as per national

standards,including TSG21-2016, NB/T47004-2009, GB150.1-4-2011, GB/T1512014, GB/T14296-2008

and etc. 10.Q: What is quality inspection procedure to

maintain product quality?A: Tranp has provided professional

inspection regulation for Final quality controls for all products,

to strictly control the quality of products from our

warehouse About Warranty:We promise 1 year guarantee,

all reasonable relevant cost will be undertaken by us in the first

year if our heat exchanger fails to work due to quality problem,

only the free repairing operation guide is available in

the rest of years via E-mail /Fax/Phone Company

profile: /* January 22, 2024 19:08:37

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about High Performance of Brazed Plate Heat Exchanger in Food Industry

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup