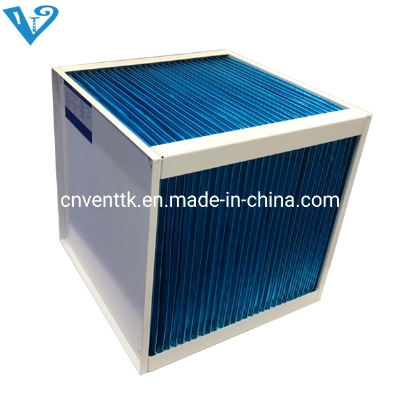

Air to air plate heat exchanger IntroductionThe heat exchanger

core is the major part of air to air ventilation system.When the

air is forced to pass through the heat exchanger core from two

different air channels,the energy and humidity are transfered by

the plates,so as to save the energy.Outdoor air and exhaust air is

separated by thermal conduction plate,avoid

cross-contamination,make sure clean outdoor air.Base on different

air channel,they can be divided into cross flow,counter flow and

cross&counter flow;base on material can be divided into

sensible and enthalpy heat exchanger core.Heat exchanger core have

compact structure,no running parts,strong reliability and long

service life. ERA Cross Flow Heat Exchanger CoreCross

flow heat exchanger core is made of antiseptic hydrophilic / epoxy

coating aluminum foil and galvanized sheet cover. The air is forced

to crossover through the heat exchanger core, two airstreams never

come into direct contact, avoid the transfer of any smell and

moisture. It is usually being used for recovering energy at

residential, commercial and wind power industry ventilation

systems. ERB Counter Flow Heat Exchanger CoreCounter flow heat

exchanger core is made of antiseptic hydrophilic / epoxy

coating aluminum foil and galvanized sheet cover. The air is forced

to counter through the heat exchanger core, two airstreams never

come into direct contact, avoid the transfer of any smell and

moisture. It is usually being used for recovering energy

at industry ventilation system, such as: base station /

outdoor cabinet ventilator and so on. ERD Cross&Counter

Flow Heat Exchanger CoreCross & counter flow heat exchanger

core is made of antiseptic hydrophilic / epoxy coating

aluminum foil and galvanized sheet cover. A part of air is cross

flow, and the other is counter flow,two airstreams never come into

direct contact, avoid the transfer of any smell and moisture. It is

usually being used for recovering energy at residential household,

commercial and industry ventilation systems. ERC Enthalpy

Heat Exchanger CoreHeat exchanger core is made of fireproof

and antibacterial fibrous paper and ABS framework, the air is

forced to crossover through the heat exchanger core, two

airstreams never come into direct contact, avoid the transfer of

any smell and moisture. It is usually being used for residential

ventilation system, in order to recover the e ·Material

of sensible heat exchangerThe sensible heat exchanger core is made

of high quality hydrophilic coating aluminium foil, with fast

thermal conductivity, no secondary pollution and high heat transfer

rate. According to different occasion, the epoxy coating aluminium

foil is able to choose from, which with higher corrosion

resistance. The thickness of aluminium foil is from0.1mm ~

0.3mm.·Material of total heat exchangerThe total heat exchanger

core (paper core) is made of fireproof and antibacterial fibrous

paper, which have high moisture permeability, good airtightness,

antirends, aging resistance, anti-mildew features, the framework is

made of ABS material, which is not easy to break, long service life

and good impermeability. The heat exchanger core not only transfer

energy but also moisture, avoid air cross-contamination, in order

to achieve high efficiency.(Types)(CO2)(NH3)(CH3)(H2O)(Fiber

clearance)(Molecular Diameter)0.3240.3080.3240.2880.3Reference

valuePlate type sensible heat

exchanger ·Application EnvironmentAIR-ERV air to air heat

exchanger core are widely used for different industry air

exchanger, heat recovery, cooling or heating and dehumidification.

Such as in HVAC, Telecom, Power Supply, Textile Industry,

Automobile, Food Industry, Agriculture, Animal husbandry, Tobacco

barn, Drying industry, Welding industry, Boiler Industry and so

on.·FeatureAdopt antiseptic hydrophilic aluminium foil, resistant

to corrosion, with long service life.Apply to special occasions of

epoxy resin aluminum foil, corrosion resistance stronger.Many size

hrat exchanger core ( plate distance 2.5 ~ 10mm )

for your choice.Module structure, any sine can be praided, no

running components, low maintenance cost.Compact struxture, small

volume, suitable for various occasions.·Production TechnologyThe

surface of heat exchanger core was processed with spiral wave heat

transfer enhancement techniques, increased the 10% heat transfer

area.Convex and concave air channel, ensure the strength and

tightness of heat exchanger core, could bear high pressure.Cross

air channel, double folding process of the face side edges,which is

equal to 5 times material thickness, ensure the high intensity and

tightness.All joints are airproofed by airproof glue, ensured that

the heat exchanger has excellent air

tightness. The antiseptic galvanized

sheet framework, failure-free operationSpiral layer edges heat

transfer enhancement techniques, ensure the intensity and

tightnessFive layer edges process of the face side edges, ensure

the high intensity and tightnessPlate joint seal pr

Related products about Factory Direct Sale Aluminum Brazed Plate Air Heat Exchanger

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup