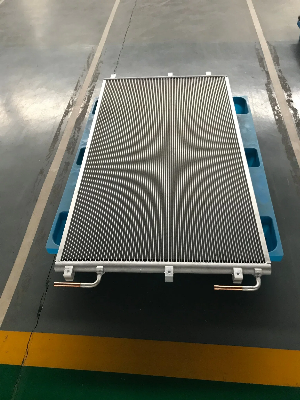

microchannel aluminum fin heat exchanger for chillerMicro channel

heat exchanger (MCHE) is a highly compact heat exchanger, whole

body aluminum structure, the diameter of a single control

refrigerant circulating about 1MM. Compared with conventional

finned tube heat exchanger, MCHE using micro-sized heat transfer

technology, smaller, lighter, heat rate increased by 50%, 50% less

refrigerant charge fluence, fan power consumption is reduced

accordingly. With rising raw material prices, air-conditioning

product standards and environmental requirements continue to

increase, micro channel heat exchanger is gradually replace

traditional heat exchangers, and has been widely used in

various fields, such as home air conditioning, commercial air

conditioners, precision computer room air conditioners, heat pumps

water heaters, refrigeration, air conditioning containers, train

air conditioning, automotive air-conditioning and other

fields.Suitable refrigerants: R22, R134a, R407C, R32, R410A;maximum

working pressure: 4.2-4.5MPa;Use medium temperature: -30 °C ~ + 120

°C;Applicable Relative humidity: 95% RHMCHEs have an ingeniously

simple design-made entirely of all aluminium which is not only

lightweight but also prevents galvanic corrosion. The

refrigerant-carrying tubes are formed to optimise heat transfer,

thus enabling the production of more compact, but equally

effective... MCHE offer a long list of features not

found in other heat exchangers. Parallel flow increases performance

by up to 45% compared to traditional tube and fin heat

exchangers. Its special circuit design reduces internal

pressure drop on the gas side by more than 65%, which

produces significant savings in compressor energy consumption and

weariness. Its slim design and its thin cross flow tube

profile decreases air pressure drop by 25% also bringing

considerable advantages: smaller fans, less noise and lower

electricity consumption.Benefitsa. Compact overall design - up to

30 percent smaller and lighter than existing tube and fin

productsb. Compact, reduced coil size meets the market's need for

less storage space, easy installation, and aestheticsc. Superior

thermal performanced. Aluminum construction yields high durability

and is easy to recyclee. Easy to handle, minimizing fin damagef.

Substantial refrigerant charge reduction compared to tube and fin

designs, enhancing environmental friendliness and helping reduce

operating costsg. Helps original equipment manufacturers meet

high SEER (Seasonal Energy Efficiency Ratio) requirementsPackaging

& Shipping1. Export carton,or according to customer's

requirements2. Generally 30days after received your deposit ,will

send to Ningbo or Shanghai port.Our factoryContact

/* January 22, 2024 19:08:37 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Microchannel Aluminum Fin Heat Exchanger for Chiller

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup