A bucket wheel excavator [1] (also a bucket wheel excavator or

wheel bucket excavator) is a type of bucket excavator that uses

multiple buckets mounted on runners mounted on the front end of the

boom to dig continuously. It is used for the excavation of a large

number of earthworks, the stripping and mining of the mine and the

loading and unloading of large material yards, with high

productivity and large digging force, and can directly excavate

harder soils. In large-scale buildings, water conservancy projects

and mines, it is often matched with transportation equipment to

form a continuous operation line. Bucket wheel excavators are

classified into small, medium, large, extra-large and jumbo

according to productivity or weight. Large-scale bucket wheel

excavators have large digging force and are often used in mining.

Wheel bucket excavator is gradually developed on the basis of chain

bucket excavator, single bucket excavator and other mining

equipment, is an ideal multi-bucket excavation equipment in

continuous operation equipment, and is also one of the largest

complete sets of excavation equipment in the world. The wheel

bucket excavator is gradually developed on the basis of chain

bucket excavators, single bucket excavators and other mining

equipment, which is an ideal multi-bucket excavation equipment in

continuous operation equipment and one of the largest complete sets

of excavation equipment in the world [2]. Wheel bucket excavator

has many advantages such as continuous operation, large production

capacity, high efficiency, adaptation to complex coal seam

selection, large transportation slope, simple operation, convenient

maintenance, easy to achieve modern management, etc., especially

suitable for large-scale open-pit mine high-efficiency mining

operations, mainly used in open-pit mine to strip topsoil, excavate

useful minerals, pile up operations, load to vehicles or conveyor

belts, etc., in addition to the mixing yard, storage yard,

large-scale water conservancy and earthwork are gradually more and

more widely used. The wheel bucket excavator is mainly composed of

6 parts: walking system, slewing system, working system, conveying

system, electric drive system, and hydraulic system, and its main

features are [4]: (1) Walking system: Most wheel bucket excavators

adopt crawler walking system, and a few adopt walking walking

system. Judging from the relevant information, most of the medium

and small wheel bucket excavators use double tracks, while large

wheel bucket excavators use multiple tracks (three tracks or four

tracks), which can reduce the specific pressure of the equipment on

the ground. (2) Slewing system: composed of turntable and slewing

drive device, etc., there is a power unit, a driving device,

control equipment and a control room on the turntable, etc., due to

the use of slewing support bearing, the drive device can make the

turntable rotate 360 ° around the vertical axis. (3) Working

system: It is composed of bucket wheel, boom, luffing mechanism and

driving device. The bucket wheel is mounted at the front end of the

boom and is a rotating wheel that evenly distributes several

buckets. The rear end of the boom is hinged on the mast of the

turntable, and the boom is rotated by wire rope or hydraulic

cylinder, so that the bucket wheel can carry out excavation

operations on different working faces. There are two main types of

boom lengths: fixed and retractable. The bucket wheel drive device

consists of an electric motor, a safety coupling and a reducer,

etc., which are arranged on the side of the front end of the boom

and are used to drive the bucket wheel to rotate. (4) Conveying

system: It is composed of a receiving conveyor belt, a hopper and a

discharging conveyor belt. In addition, the connecting bridge wheel

bucket excavator is also equipped with a transfer conveyor belt on

the connecting bridge. (5) Electric drive system: Except for some

small wheel bucket excavators that use diesel generator sets, other

wheel bucket excavators use external power converter units. (6)

Hydraulic system: mainly use hydraulic cylinders to drive the

bucket wheel arm and discharge arm to lift. Cantilever bucket wheel

is the main product of Changchun power generation equipment, and

its market share has been in the forefront of the industry for many

years. Boom luffing type is the use of wire rope winch mechanism or

hydraulic cylinder to traction forearm luffing; The integral

luffing type is that the entire superstructure position is made

into one, and the superstructure luffing is realized by the

traction of the hydraulic cylinder; Ordering Requirements: Please

provide the following information and parameters when ordering: A.

Material characteristics, environmental conditions, system

parameters B. Stockpiling capacity, reclaiming capacity, stockpile

height C. Radius of rotation D. Gauge and wheelbase E. Forms and

requirements of bucket wheels, tape machines, slewing, luffing,

door seats, tail cars,

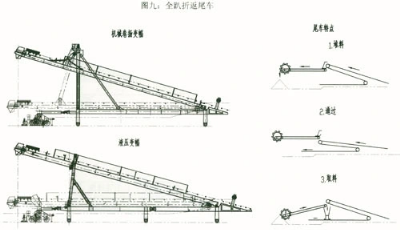

Related products about Full Turnaround Back to The Tail Car Bucket Wheel Stacker Reclaimer

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup