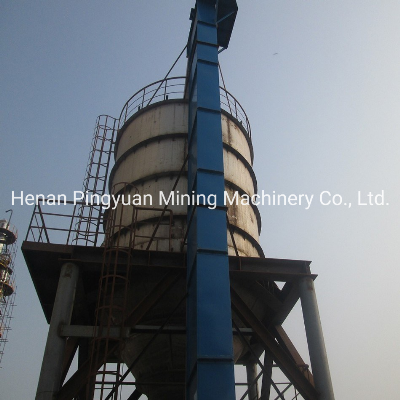

sand chain bucket elevator made in chinaIntroductionSilo bucket

elevator is specially designed to associated with silo which is

applicable to lift material in small size and density. Steel or

plastic buckets are optional when you purchase,rubber belt or chain

type bucket elevator are optional when PK engineers configure the

proper model.Meanwhile,silo bucket elevator is totally enclosed

type to prevent dust flying.Silo bucket elevator is widely used for

conveying powder, granular and non-small-block mill and grinding of

small materials, such as coal, cement, stones, sand, clay, ore and

so on.Advantages and Features1.Superior design-Low power required,

effective inflow feeding & guiding discharge, steady

operation,compact structure.2.Vast range of application- Almost no

limitation for lifting material forms and properties.3.Free from

pollution- Good sealing condition could effectively reduce the

environmental pollution.4.Advanced technology-Excellent design &

reliable manufacturing way has greatly ensured the overall

machine.5.Designed to fit your operation-Silo bucket elevator can

be customized to meet different capacity and working

site.6.Customized driving unit-Domestic or Imported brand can be

chosen as per client's requirement.Technical Parameter: Silo

Bucket ElevatorModelBelt Width mmHead Pulley Dia. mmTail Pulley

Dia. mmBucket Speed m/sHead Shaft Rotation Speed r/minSteel

Bucket Volume LSteel Bucket Pitch mmSteel Bucket Capacity

t/hPlastic Bucket Volume LPlastic Bucket Pitch mmPlastic Bucket

Capacity

t/hTZD2002006305001.7653.51.21300101.21300101.7653.5150201502026012530125302.7583.31055010550TZD2502506305001.7653.32.35150302.35150301.7653.312550125502.4273.51258012580391.9125100125100TZD3003007105651.9352.56215803.1145502.260215100145803.0582.2215150145100TZD4004007105651.9352.58.42151006.1195802.2602151501951003.0582.2215200195150TZD5005008006551.974710.921515011.52551002.252.82152002551503.174215300255200TZD6506508006552.252.82X62152002X3.11451502.76662153001452003.8792.5215400145300TZD80080011409302.541.62X8.42154002X6.11952003.1552.52155001953003.9466215600195400Selection

Conditions ♦Material to be processed: _____♦Material is

corrosive or not: ____ (Ps. Yes or No)♦Handling capacity (Ps. It

means the total♦Working environment is indoor or

outdoor:________material capacity feeding from the inlet):

_____t/h♦Material is liquid or not:___________(Ps. Yes or No)♦Bulk

Density: _____t/m3♦Working environment temperature:

_______ ºC♦Lifting height of the elevator (distance

between♦Upstream equipment (Ps. It means what kind of inlet

and outlet):__________mequipment is used to feed the material):

_____♦Max. granule size of the feeding material: ____mm♦Downstream

equipment (Ps. It means what kind of♦Percentage of Max. granule in

material:_________%equipment is used to discharge the material):

_____♦Material temperature: _____ºC;♦Working power supply: _____V

______HZ ♦water content:____% We mainly provide the

following equipments :Vibrating ScreenRotary vibrating

screenUltrasonic vibrating screenGyratory screenTrommel

screenLinear vibrating screenCircular vibrating screenDewatering

screenVibrating feederBelt ConveyorBelt conveyorSidewall belt

conveyorPortable belt conveyorShuttle conveyorTripperBucket

ElevatorEfficient bucket elevatorBelt bucket elevatorRing chain

bucket elevatorPlate chain bucket elevatorCement bucket

elevatorSilo bucket elevatorScrew ConveyorU-type screw

conveyorCement screw conveyorPipe screw conveyorScraper

ConveyorHorizontal scraper chain conveyorIncline scraper chain

conveyorGrain scraper chain conveyor /* January 22, 2024

19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Sand Chain Bucket Elevator Made in China

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup