About UsHeadquartered in Xinxiang City, Henan Province, China,

domestic well-known screening and conveying equipment city, PK

Machinery has enjoyed more than 50 steady years of successful

growth, and now it has been widely acknowledged as a trustworthy

and professional manufacturer in the field of bulk material

handling equipment, including vibrating screen, vibrating feeder,

belt conveyor, bucket elevator, screw conveyor, scraper chain

conveyor and associated spare parts in complete

specifications.Product DescriptionGet a price at

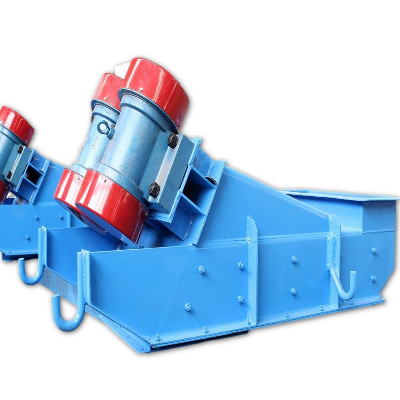

once!IntroductionVibrating Feeder is a kind of linear direction

feeding equipment, It consists of feed spout, vibration body,

vibrating motor, damping device. It can feed material for belt

conveyor, vibrating conveyor, bucket elevator, vibrating screen,

crusher etc.Working Principle and ApplicationThe feed process of

the vibrating feeder is achieved by the feed spout do line

reciprocating vibration periodically which is forced by the special

vibrating motor. When the vertical component of the feed spout

vibrates, the accelerated speed is bigger than the gravitational

acceleration, the material will be upthrow and jumping forward

along a parabolic path. Due to the continuous exciting of the

vibrating motor, the feed spout will vibrate continuously and the

material in the feed spout will jumping forward continuously, so

that the purpose of feeding material is achieved.Vibrating Feeder

is widely used in pharmaceutical, automotive, electronic, food

processing, packaging, glass, steel, construction, recycling,

plastic industry etc. Advantages and Features1.Smooth

operation, large feeding capacity with high efficiency2.Low energy

consumption,stable vibration,long service life3.Characterized by

even feeding, excellent continuity and adjustable vibrating

force4.Eccentric block as the main source of vibration5.easy

maintenance and the enclosed type can prevent dust

pollution6.Simple structureProduct ParametersGet a price at

once!Technical data:ModelFeeding Size (mm)Processing

Capacity (t/h)Model of Vibrating

MotorPower (kW)RPM(r/min)Double Amplitude (mm)Vibrating

Force (N)ZG-256025YZO-2.5-40.25x215002-35000ZG-306030YZO-2.5-40.25x215002-35000ZG-609060YZO-5-40.4x215002-410000ZG-8016080YZO-5-40.4x215002-410000ZG-100210100YZO-8-40.75x215002-516000ZG-200270200YZO-8-40.75x215002-516000ZG-300300300YZO-17-40.75x215002-534000ZG-400300400YZO-17-40.75x215003-534000ZG-500300500YZO-17-40.75x215003-534000ZG-750400750YZO-30-62.5x210004-660000ZG-1200 4001200YZO-30-62.5x210004-660000ZG-1800 4201800YZO-75-65.5x210005-8150000ZG-2000 4202000YZO-75-65.5x210005-8150000 Selection

Conditions♦Material to be processed: _____♦Working environment is

indoor or outdoor: _____♦Handling capacity (Ps. It means the

total♦Working environment temperature: ______ ºCmaterial

capacity feeding from the inlet): _____t/h♦Upstream equipment (Ps.

It means what kind of♦Bulk Density: _____t/m3equipment is used to

feed the material): _____♦Material temperature: _____ºC;♦Downstream

equipment (Ps. It means what kind of♦Water content:____%equipment

is used to discharge the material): _____♦Material is corrosive or

not: ____ (Ps. Yes or No)♦Installation forms: ___(Ps. Hanging-type

or seat-type)♦Material is sticky or not: ____ (Ps. Yes or

No)♦Working power supply: _____V ______HZ We mainly provide

the following equipments :Vibrating ScreenRotary vibrating

screenUltrasonic vibrating screenGyratory screenTrommel

screenLinear vibrating screenCircular vibrating screenDewatering

screenVibrating feederBelt ConveyorBelt conveyorSidewall belt

conveyorPortable belt conveyorShuttle conveyorTripperBucket

ElevatorEfficient bucket elevatorBelt bucket elevatorRing chain

bucket elevatorPlate chain bucket elevatorCement bucket

elevatorSilo bucket elevatorScrew ConveyorU-type screw

conveyorCement screw conveyorPipe screw conveyorScraper

ConveyorHorizontal scraper chain conveyorIncline scraper chain

conveyorGrain scraper chain conveyor /* January 22, 2024

19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about New Spiral Auger Coal Feeders with Stove

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup