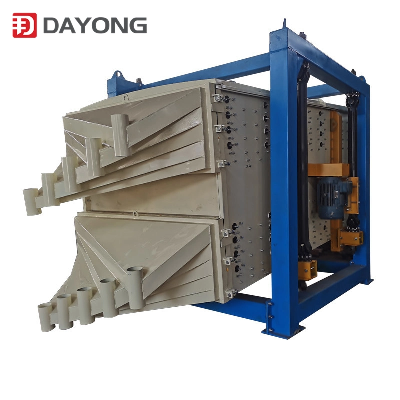

Product DescriptionDYFY Square swing screen is the perfect

combination of high capacity and high precision. Vibrating and

rocking motion is generated by the vibrator and transmitted to the

screen surface, so that the material is quickly dispersed at the

front of the screen machine, thereby achieving efficient screening.

DYFY screen is widely used in metallurgy, abrasive, non-ferrous

metals, non-ferrous metals, chemical, food, and other

industries.Working PrincipleThe working principle of the square

tumbler screen is that after the start of the screen machine, the

rocking body of the screen machine, i.e. the screen box, moves back

and forth under the action of inertia force, and the screen box

drives the screen surface to oscillate periodically, so that the

material on the screen surface can make a directional jump motion

with the screen box. During this period, the material smaller than

the screen aperture falls into the lower layer through the screen

hole and becomes the material under the screen, and the material

larger than the screen aperture is rolled continuously. After the

jump movement, it is discharged from the discharge port, and

finally the screening work is completed.Machine Type1.Large screen

size, unique multi-layer grading design, one machine is divided

into two groups, one is used in multiple units, and the output

doubles.2.The fully enclosed structure, the dust is not flying, the

sieve machine has low vibration and low noise, and meets

environmental protection requirements.3.Flexible screening, the

acceleration is 4-5 times lower than that of ordinary vibrating

screen, and the service life is increased, thus reducing

maintenance costs.4.Changing the net is more convenient, simple to

operate, firm and reliable.5.Large electrostatic spray molding

process, the equipment is more beautiful, wear-resistant and

rust-proof.Detailed Photos1.Sealing stripVibrating screen

incorporates food grade safety seals where they need to be joined.

Not only can a good seal be achieved to prevent leakage, but also

the safety of the material is guaranteed.2.Replace screen

quicklyvibrating screen frame adopts the track type design, which

is convenient for customers to change quickly. Only two people can

change the screen in one minute3.Universal shaftThe whole sieve box

of the vibrating screen is connected by the universal axis, when

the sieve machine does the rocking movement, the universal axis

also follows the rotation, plays the role of buffering to the

rotating power, damping, so that the whole sieve machine runs more

smoothly.4.Carbon steel frameworkDue to the large volume and large

weight of the whole screen machine, the rotation of the screen

machine requires better stability, so it is made into a rectangular

frame structure to improve the stability of the product.Product

ParametersModelScreen SizeScreen Area (m2)Inclined Angle (°)Layer

(s)Power (kw)Allow Rotation NumberScreen Box

Stroke (mm)DY-FY15361.5m*3.6m5.4-95.4±31-97.5180-26025-60DY-FY20402m*4m8-95.4±31-915180-26025-60Application

Industry1. Mainly used for screening, filtering, grading and

removing impurity for all kinds of powder, particle, and liquid.2.

Mainly suitable materials: chemical, medical powder and particle,

coating, pigment, cosmetic, grease, resin, ceramic sauce,slurry,

quicklime, fireproofing powder, metallurgy powder, starch,flour,

rice flour, carbon powder, graphite powder, manganesepowder,

sewage, waste oil, dung, etc.Company ProfileWe are direct factory

of vibrating screen, conveyor equipment and mixer for many years,

we are glad to build long lasting business relationship with you.

We have the enterprising and energetic team of excellence who are

dedicated to their career. More staff work for us, including

technicians and engineers with senior title. Mainly produce rotary

vibrating screen, linear vibrating screen, ultrasonic vibrating

screen, test sieve shaker, belt conveyor, screw conveyor, vacuum

conveyor, dust-free feeding station, etc.Related ProductsFAQ1. How

can we hanld the problem of blocking mesh ?Except the ultrasonic

vibrating screen adopts ultrasonic cleaning system, other vibrating

screen adopts bouncing ball and PU ringbelow every deck to cleaning

screen surface.2. How about the sealing of this machine ?Between

two decks, there are silica gel ring to seal. Then the clamp would

lock two decks tightly with the extended copper nut.3. Could this

machine be refitted or designed to suit to my production line ?All

of machines in our company could be customized by clients' specific

requirement such as the height from outlet to ground, theinlet

shape, the outlet shape and the gate design on first deck.4. How

can I get the matched spares for maintaining ?The matched spares

such as seal ring, bouncing ball, screen surface, clamp screws and

nut could be ordered one set or more ascustomers' need.5. How many

payment terms can I choose ?L/C, T/T,Western Union and Paypal are

available./* January 22, 2024 19:08:37 */!function(){funct

Related products about 20t/H Large Capacity Rotex Gyratory Sand Sieving Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup