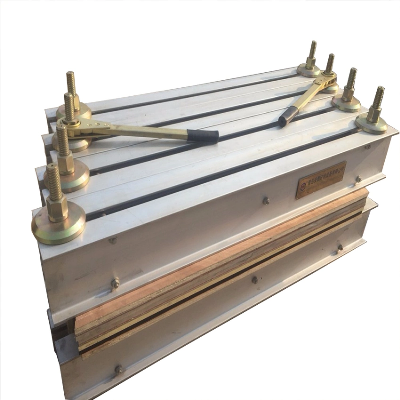

Steel cord conveyor belt vulcanizing joint curing pressSteel cord

conveyor belt vulcanizing joint curing press1. Technical

parameterNONameA=1200mm1Tape joint vulcanizing machine1

set2 Type ZLJ-1200×8303Sulfide tape width12004Vulcanizing

machine work press (Mpa)1.0-3.0 Mpa(adjustable)5Vulcanizing

temperature145ºC6Surface temperature difference (ºC)±2ºC7Heating up

time(Normal atmospheric temperature 145ºC)≤15min8Temperature

regulating range (ºC)0-200ºC9Timing adjustment

range0-99min10 Sulfide board

size1420*830mm11weight850kg12Voltage380V13Work

press0---1.8mpa14Power15.5kw2. Random accessories:1) Top and bottom

heating plate:2 pcs(1420×830mm)(tickness25mm);2) Pressure water

bag: 1set(1420×830mm);3) press plate:

1set(1420×830mm);4) Heat insulation board:

2set(1420×830mm);5) Pressurized beam: 5 group;6) The

large bar: 5 set;7) Control box: 1set(All using

CHINT electric);8) Input line: 1set(Combined air plugP40);9)

Output line: 2set(Combined air plugP40);10) Sensors:

2set(Internal burial)11) Electric pressure pump:1set;12) High

pressure water pipe:1 root;13) Ratchet wrench:2 bundle.ModelBelt

width(mm) Power(kw) DimensionsWeight(kg)(L*W*H

mm)ZLJ-650*8306509.51400*930*800500ZLJ-650*100010.81400*1100*800580ZLJ-800*83080011.21550*930*1000550ZLJ-800*100013.51550*1100*1000640ZLJ-1000*830100014.11750*930*1000600ZLJ-1000*100015.71750*1100*1000700ZLJ-1200*830120016.51950*930*1000700ZLJ-1200*100017.21950*1100*1000810ZLJ-1400*830140018.62150*930*1000830ZLJ-1400*100020.72150*1100*10001000ZLJ-1600*830160021.52350*930*10001050ZLJ-1600*100022.32350*1100*10001250ZLJ-1800*830180023.32550*930*10001150ZLJ-1800*100025.62550*1100*10001350ZLJ-2000*830200027.22750*930*10001900ZLJ-2000*1000302750*1100*10002200ZLJ-2200*830220029.22950*930*11002000ZLJ-2200*100034.12950*1100*110024003.

Test Before DeliveryBefore leaving factory, the machine needs to

pass 24 hours' test running and guarantee no oil leakage and

seeping to avoid unnecessary quality

problems.4. PackagingEquipment painting completed before

delivery, and then wrapped with stretch film, to protect the

painting surface, we use wooden packaging outside.The key parts of

the machine, such as electronic control box, will be wrapped by

shockproof packaging materials, and then packed in wooden

cases.FAQ 1. Delivery time of the rubber machines?This is

specially designed machine according to your specific

requirement. From engineer designing to production completion,

it needs about 25 to 35 days. 2. What does your factory do

regarding quality control? We pay much more importance to

quality control from the very beginning to the end of

production. Every machine will be fully assembled and

carefully tested before shipment. 3. What's the machine

quality guarantee?Quality guarantee time is one year.We choose

world famous brand components to keep our machine in perfect

working condition. 4. How can I trust you to deliver the right

machine as I ordered?We will absolutely deliver a good quality

machine as we discussed and confirmed in the order.The core of our

company culture is innovation, quality, integrity and efficiency.

Also we have had much good cooperation with world famous rubber

production manufacturers. If you come to our factory, we can show

you're the user around us. 5. How can we go to your side?We

are located in Qingdao City, Shandong province, China. The name of

airport is Qingdao Liuting airport.We will pick up you at the

airport.If you interested in our products mentioned above, kindly

let us know by return email. Then I will supply you with further

information. Meanwhile, welcome to visit our factory!/* January 22,

2024 19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Steel Cord Conveyor Belt Vulcanizing Joint Curing Press

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup