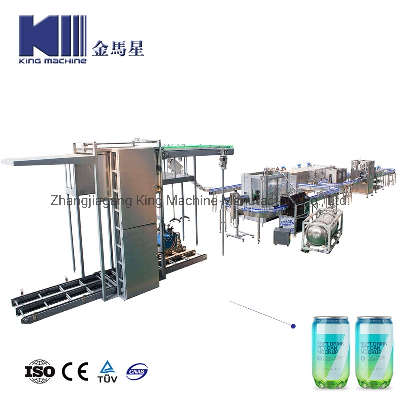

Automatic Aluminum Can Beverage Filling and sealing machine* we

provide the complete pop cans / tin can filling and package

solution ,from juice processing system , water treatment plant

, can depalletizer ,can rinsing machine ,can filling & sealing

monoblock machine ,leakage check,liquid nitrogen dosing machine

,pasteurizer tunnel ,blow dryer ,carton package ,film package

system ,which is widely used for the beverage ,beer ,juice , CSD

industry and so on.Product Description Technical parameter

:beverage drink can filler

machineryModelGDF12-1GDF18-4GDF24-4GDF32-6GDF40-8Capacity(cans/hour)20008000120001500020000Suitable

containerAluminum Can / Tin Can / Plastic CanCan diameterDia50

~ dia99mmCan height (mm)70-133mmCompressor airIsobaric filling

/ normal pressure fillingApplicationBeverage Can Filling

MachineTotal power (kw)2.4kw4.4kw5.2kw6.2kw7.2kwOverall

dimensions2.5*1.9m2.8*1.9m3.2*2.15m3.5*2.5m3.8*2.8mHeight2.3m2.5m2.5m2.5m2.5mWeight(kg)2500kg3200kg4000kg4500kg6500kgCola,

, Soda, speaking water, cocktail, flavored water...the variety

of carbonated beverage is ever changing. New trend, new products

and new packaging are emerging continuously. For carbonated filling

machines, how to rise up the filling temperature to reduce energy

consumption? How to reduce foaming? How to keep accurate

filling?How to avoid the residuals in the neck? How to preserve the

CO2...it is not an easy task to handle all these challenges.

However, no matter what products, King Machine will achieve your

target with the best technology. Meanwhile, King Machine filling

machine can realize multiple functions in one equipment. One

machine can do water, carbonated drinks and hot filling products.

Detailed Photos The equipments constituteMainly the

filling machine is from the filing urn and the filling valve. After

can is washed, it is transferred to the filling machine through the

middle spider. The star wheel will stuck can and sent them into the

filling machine. The base will support the can to rotate around the

filling machine, and the roll will open, the liquid will into

can. The filling valveThe filling valve is one of the key

parts that the filling machine, the filling valve is make up of the

valve core, valve body ,valve seat , umbrella?wide liquid

valve---etc---1. When can from in the center the star round enters

a can-base of board, the filling valve taking the valve coat, the

valve core is together up move, at this time 0 type roll 1 take off

with the valve seat to open, enter the filling district.2.The

material continue downflow, until the bottle filling up ,when the

rolls round to carry on the cam, the filling valve to move up,0

type circle 1compress tightly the valve body, make the material no

longer enter the valve tube of the valve core. Cap screwing

MachineThe cap screwing machine is composed of frame, slide way,

cap screwing device, transmission and others.The transmission of

the cap screwing machine is drive to the gear by the reduce, the

power is transferred to the cap screwing head through the hollow

main axle.The can is not rotating, the four small rolls will rotate

and press cap. The cam is fixed. The cap is sent into the gear ring

of the screwing cap head through the stirring device and slide way.

When there is a can on the convey belt, a cap will move down with

the rotating of the screwing cap head and screw the cap on the can

mouth.Flow chart :Complete pop cans / tin can filling and

package solution ,from can depalletizer ,can rinsing machine ,can

filling & sealing monoblock machine ,leakage check,liquid nitrogen

dosing machine ,pasteurizer tunnel ,blow dryer ,carton package

,film package system.Auxiliary machines for aluminium can filling

production line Can de-palletizer•replace the manual

can arrangement•increase production efficiency•plc programmable

computer automatic controller ,photo-electricity switch,over

travel-limit switch.Carbonated Drink Mixing Part•Wide range of uses

- The system can handle a wide range of products such as carbonated

drinks, juice drinks, etc.•Structural Hygiene - All parts in

contact with fluids are of high quality stainless steel, all tanks

are equipped with CIP ball for easy cleaning.liquid level checkerIt

matches on the can line for checking the level of beverage, if the

filling quantity do not reach the standard which will be kick out.

From that it can keep the product safety.Vacuum inspector1.

Production capacity: 0~150 cans/min2. Using range: Can

diameter:

φ52.5~φ99mm

Can height: H65~H166mm3. Power: 500W4. Weight: 60kg5.

Dimension: (length×width×height) 530×150×350mmWarming Tunnel For

Aluminum Can1. High reliability conveying device and flexibility

speeding system2. high effective spraying system3.The temperature

can be controlled flexibly and easily setPE film packaging

machineAutomatic PE film heat shrink wrapping machine is suitable

for wrapping of such products as pop top, mineral water , bottles.

beer, drinks etc. Working with PE film shrink tunnel to p

Related products about Beverage Juice Industry Can Filling Machine Production Line

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup