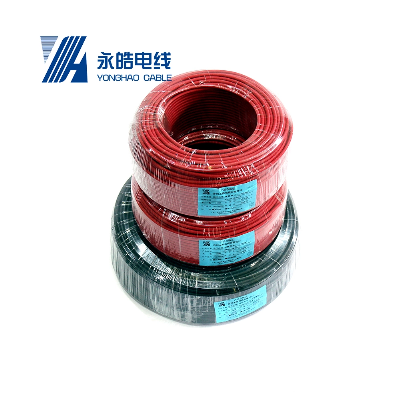

Usefor Solar Plants Distribution SystemAmbient

Temperature-40ºC~+90ºCTest Voltage6500V, 50Hz, 5minAmbient

Temperature25 Years (TUV)OriginChinaProduction Capacity 1200km per

day CertificationTUVProduct NameDC Solar PV CableColorBlack ,Red

,Brown,Grey Or CustomizedSpecification1.5mm2, 2.5mm2, 4.0mm2,

6.0mm2, 10.0mm2, 16.0mm2, 25.0mm2, 35.0mm2Number of CoresSingle

Core,Two CoreTransport PackageDrum or RollRated

voltageAC:Uo/U=0.6/1.0KV DC:1.0KVVoltage test on completed

cableAC:6.5KV DC:15KV,5minWeathering /UV-resistanceHD605/A1ACID and

Alkali resistanceEN60811-2-1Cold bending testEN60811-1-4O-zone

resistance at complete cableEN50396Flame testIEC60332-1Max

Temperature at conductor+120ºCService Life25

years(-40ºC~+90ºC)ApprovalsTUV RheinlandHOT PRODUCTS63930 IEC

131Electrical solar cableTUV H1Z2Z2-K In the solar

photovoltaic power generation system in the low-voltage DC

transmission part of the cable, because the use of the environment

and technical requirements are different, the connection of

different parts have different requirements, the overall factors to

consider are: cable insulation performance, heat resistance and

flame retardant performance, aging performance and wire diameter

specifications.1. The connection cable between the solar cell

module and the module is generally connected directly by the

connection cable attached to the module junction box. When the

length is not enough, a special extension cable can also be used.

According to the different power size of the component, this kind

of connecting cable has a cross-sectional area of 2.5m square

meters, 4.4m square meters, 6.0m square meters and other three

specifications. This kind of connecting cable uses double

insulation outer skin, has superior protection against UV, water,

ozone, acid, salt erosion ability, superior all-weather ability and

wear resistance.2. Use a multi-strand flexible cable that passes

the UL test to connect the battery to the inverter. Choosing short

and thick cables can reduce system losses, improve efficiency, and

enhance reliability.3. The cables connecting the battery array to

the controller or DC junction box must also use multi-strand

flexible wires that pass the UL test. The cross-sectional area

depends on the maximum output current of the battery array.The

cross-sectional area of the DC cable at the named location shall be

determined according to the following principles: Cables connecting

solar modules, batteries and batteries, and AC load cables.

Generally, the rated current of the cables is 1.25 times of the

maximum continuous working current of each cable. For connecting

cables between the solar cell array and the square array, and

connecting cables between the battery (group) and the inverter, the

rated current of the cable selected is generally 1.5 times of the

maximum continuous working current in each cable. /* January

22, 2024 19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Two Coresolar System Photovoltaic Flexible Copper PV Solar Panel Electrical Wire 2.5mm2 4mm2 6mm2 10mm2 DC Electric Solar Fiber Optic Cable

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup