Product Description This top-quality high-tensile deer and

wildlife fence is ideal for the confinement of small and large

animals, from sheep and goats to deer and elk. The deer and

wildlife fence is woven from high tensile wires, either

12½ top and bottom with 14 gauge filler ZA (Zinc/Aluminum)

coated or 12½ gauge Class 3 galvanized. You are assured of a

long-lasting fence. The minimum tensile strength of the

12½ gauge fences is 140,000 psi. Strong fixed

knot construction - one-piece vertical wires are tightly

fastened to horizontal wires by a third wire which wraps around the

intersection. Vertical wires cannot unwind under pressure.

Although the joint is firmly held, the design has enough inherent

flexibility to allow the fence to conform to uneven terrain.

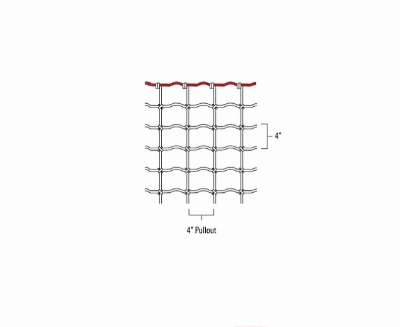

Tension curves in the horizontal wires allow for expansion and

contraction. Spacing of horizontal wires of deer and wildlife

fences are graduated from small at the bottom to large at the

top. Fencing Choices and ConsiderationsWhen selecting a

ranch fence, basic wire choices need to be made, including knot

type, tensile strength, gauge, galvanization, and mesh spacing. In

most applications, the best value is the fixed-knot, high-tensile,

12-gauge, Class-3 galvanized, with 6 inches or less of mesh

spacing. These combined qualities create a fence that is superior

in value based on cost and performance.Still, what exactly does all

of this mean? Read on to familiarize yourself with the different

factors that make up this best-value winner.Knot TypeThe most

familiar knot that we all recognize is the barbed-wire knot. It

consists of two wire strands twisted together and starred with

either 2- or 4-point barbs at intermittent distances.The second

type is the hinged-joint knot. This is formed by wrapping the

vertical stay wire pieces around the line wire at each

intersection.Lastly, the fixed knot utilizes a separate piece of

wire that's tightly wound and knotted around the line wire and stay

wire.Of these options, Orange Wire' choice is the fixed knot fence.

It is considered the premium option, and tests have proven it has

the highest vertical strength, moving and loosening less under

pressure.Tensile StrengthWire strength is expressed as tensile

strength. The tensile strength of a material is the maximum amount

of tensile stress that it can take before failure, for example

breaking. As such, wire strength is largely dependent on its carbon

content, and wire fencing products are manufactured using either

low-carbon or high-tensile wire.Low-carbon wire is made from a

steel rod with a carbon content of approximately 0.10%. This type

of wire is easy to work with and fairly forgiving, allowing for

increased stretching and elongation. High-tensile wire is made with

higher carbon content at approximately 0.28%. By almost tripling

the carbon content the wire strength significantly increases and

reduces stretching and elongation.Between the two options, Orange

Wire' chooses high tensile. Our product framework is among the

highest-strength steel available for fencing. With a tensile

strength of 50,000 psi, it is more than 45% stronger than standard

steel, leading to reductions in elongation, and minimizing the need

for future tensioning and repair work.Furthermore, high tensile

combined with the fixed knot produces the strongest woven-wire

fence available on the market. Pairing these together make it

highly resistant to livestock and wildlife damage, such as wild

hogs. Superior construction prevents wild hogs from breaching the

fence fabric like they do in low-tensile, field-fence wire. In

fact, the breaking strength of each horizontal, 12-gauge wire is

around 1,380 lbs. Additionally, crimps in the horizontal

high-tensile wires are installed with significant tension, so they

resist force in spring-like fashion, which helps retain shape and

strength. With proper installation, good maintenance consists of

routine checks for damage from falling trees, and that's it.

GaugeSize of wire is expressed as gauge, which signifies its

thickness or diameter. As the gauge number increases, the wire size

decreases. Basically, the bigger the number, the smaller the wire.

A lower-gauged (thicker) wire is best used for heavy animals that

press against the wire. A higher-gauged (thinner) wire is

sufficient for small, lightweight animals.In most cases, Orange

Wire chooses the 12.5-gauge diameter as the top choice in typical

ranch fence applications. Although recommended gauge varies

depending on specific needs, 12.5-gauge works for most

installations and will keep livestock safe and secure.

Professional-grade 12.5-gauge, high-tensile wire is 175% stronger

than traditional low-carbon options.Galvanized CoatingThe

galvanization process includes dipping the manufactured product in

hot molten zinc, or in some cases, zinc and aluminum. Thickness of

the galvanized coating is ranked by class, indicating its life

expectancy.Class 1 is the industry standard and has 0.28 ounces of

zinc coating

Related products about 100 FT. X 48 in. Woven Non-Climb Horse Fence 4 in. Vertical Spacing

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup