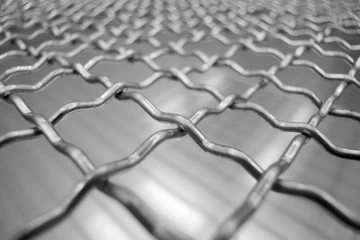

Yongkun Metal has many years' experience in the production of

various woven wire mesh, and won a large number of

foreign customers' affirmation. And our company has been

devoting commitment to technology innovation, new product

development, research in product development. The many years'

achievements of effort promote Yongkun today in the

professional field of wire mesh market.Yongkun

metal offers quality stainless steel wire mesh, woven wire

cloth and screen mesh. Our company manufactures and supplies metal

mesh products to meet and exceed our client's specific

requirements, reducing costs while increasing production

efficiency. We have a full range of 304 and 316 stainless steel

woven mesh products available for immediate shipping and we can

supply our clients with extra wide wire cloth products of up to

240″ wide and extra-long rolls of up to 2000″.Stainless steel woven

wire cloth has outstanding characteristics of resistance to the

rust, corrosion, acid, alkali, heat and chemical. Also the

stainless steel woven wire cloth has high strength and durability.

Stainless steel woven wire cloth has widely applications in the

industries, architecture, residences and other

places.Specifications Material:stainless steel wire 304,

304L, 316, 316L, 310, 314, 410, 430Weaving type: plain weave, twill

weave, dutch twillWire diameter:0.022mm - 3.5mmAperture size:Plain

weave up to 425 meshTwill weave up to 635 meshDutch weave up to 400

× 2800 meshGrade:mill grade, market grade and heavy duty

gradeFeaturesExcellent resistance to the rust and

corrosion.Resistance to the acid and alkali.Cleaner and brighter

appearance.Resistance to the chemical and harsh weather.There is no

welded point; the woven wire is long lasting.High strength and

durable.Versatility in fabrication. The stainless steel can be

fabricated to various weaving types, aperture size and diameter. It

can fit different requirements of the customers.Customized. We can

supply the standard specification of the stainless steel woven wire

cloth, and the special specifics and requirements are

available.Stainless steel woven wire mesh screen has a great

diversity of applications due to its properties of anti-acid,

alkaline-resistant, wear-resistant, heat-resistant, high-strength,

durability. It perfectly suits for sieving and filtration in acid,

alkaline environment, liquid and gas filtration in industries of

aerospace, petroleum, chemical. Also popular uses for walls and

ceilings as an alternative of wood in the construction field,

partitions, machine protection cover, security screens and window

screens, etc.We offer a variety of designs and styles of stainless

steel woven wire mesh screen to fulfill your requirements: Plain

Weave, Twill Weave, Plain Dutch Weave, Twill Dutch Weave, and

Reverse Dutch Weave.Stainless Steel Wire Mesh - Plain Weave

Stainless Steel Wire Mesh - Plain Weave is the the most common and

simplest of all weaves with apertures from 10.7mm to 0.05mm, the

diameter is almost the same for both the warp and the weave. It is

composed of weft wire warped alternately above and below creating a

wire mesh. Plain weave is also the most economical, applications

including filtration, sifting, sieve and safety equipment,

etc.Stainless Steel Wire Mesh - Twill WeaveFor heavier needs, the

twill weave is recommended. The shute wire is passed above and

under two warp wires ensuring that the weave is sturdier as this

produces a stronger and more durable wire mesh. The warp and weft

have the same diameters thus creating a close diagonal pattern.

This type of pattern is mostly used for filtration.Plain Dutch

WeavePlain Dutch stainless steel woven wire mesh screen has a

similar weaving pattern as in plain, except the diameter of warp

wire is larger than shute wire.Twill Dutch WeaveTwill Dutch weave

stainless steel wire mesh screen combines the weaving pattern of

Twill and Dutch, the larger diameter warp successively passes over

and under smaller diameter shute wire creating a tight mesh that

can withstand heavy pressure. Since Dutch weave creates a stronger

and more durable structure than plain weave does, this type of mesh

provides superior liquid filtration capabilities and it is your

ideal option for petrochemical, aerospace, pharmaceutical, mining,

and wastewater treatment facilities.Reverse Plain & Twilled Dutch

WeaveReverse Dutch Weave stainless steel wire mesh screen also uses

two different sizes of wires in weaving but reversing the method

used in Dutch Weave. The smaller wires are using in the warp

direction and are woven with a larger shute wire. The smaller wires

are woven as closely as possible to provide a finer and tight mesh

for filtering. The larger wire is used to strengthen and support

the whole mesh.ApplicationStainless steel wire mesh is widely

used for filtering, protection, feeding, decoration and printing in

petroleum, chemical, electronic, textiles, ceramics, glass,

biomedical, architecture, residences and other fields.Stainless

steel woven

Related products about Wholesale Galvanized Square Woven Wire Mesh / Stainless Steel Crimped Wire Mesh

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup