Ultra/extra clear tempered glass low iron toughened

glassUltra/extra clear tempered glass is also called low iron

tempered glass, which is made by forming compressive stress on the

surface of the glass and heating the glass up to its intenerating

temperature and then make the glass uniform cooling quickly. During

the process of cooling, the exterior part of the glass is

solidified because of the rapid cooling, while the interior part of

the glass shrinks because of slow cooling, then forming compressive

stress on the surface of the glass and tensile stress inside the

glass, thus improving the intensity and heat stability of the

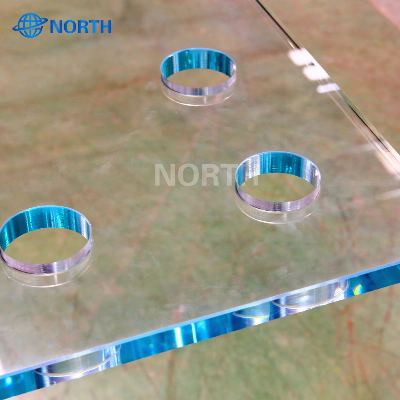

glass. Low iron tempered glass can be with holes or

cutouts/hinges/grooves/notch and processed into tempered laminated

glass, tempered insulated glass, etc. Standard: EN 12150; ASTM

1048; BS 6206: 1918; GB 15763.2-2005; AS/NZS 208: 1996

Applications: Low iron tempered glass is safety glass, which is

widely used as window glass, door glass, curtain wall glass,

fencing glass in buildings, hotels, curtain wall, etc.

Specifications: Thickness: 3-19mm low iron tempered glass Color:

Clear tempered glass, ultra clear tempered glass, brown tempered

glass, golden bronze tempered glass, blue tempered glass, ocean

blue tempered glass, dark blue tempered glass, light blue tempered

glass, F green tempered glass, light green tempered glass, dark

green tempered glass, euro grey tempered glass, dark grey tempered

glass, etc. Max specification: Flat tempered glass 3000*8000mm Bent

tempered glass 3000*5000mm, R=1500mm Considering the

characteristics of low iron tempered glass, glass size should be

confirmed before making production. Once tempered glass size is

confirmed, tempered glass can not be made mechanical treatment any

more, and otherwise, it will be broken. Competitive Advantage: Low

iron tempered glass has a very good performance of anti-curve,

anti-impact intensity, 3 to 6 times better than normal glass.

Tempered glass/Toughened glass can afford pressure over 95MPa on

the surface. Tempered glass/Toughened glass has high stability even

under temperature change of 200-300 centigrade, while normal glass

can only afford change of 70-100 centigrade. Tempered glass becomes

small sand shape if tempered glass is broken under big forces,

which guarantee safety and less loss. Safety performance: Low iron

tempered glass will appearance hurtless obtuse angles when

breakage. Strength performance: Four times more than ordinary

glass. Heat stability performance: Three times more than ordinary

glass, could bear the temperature change about 200° C. 1. Safety 2.

Tempered glass has 4-5 times strength than ordinary glass 3. Hot

stability 4. Generously satisfy with different clients' requirement

to meet different designs Low iron tempered glass is often referred

to as safety glass because it is more resistant to breakage than

normal float glass. Yet if it is broken, it usually breaks into

relatively small pieces, which are less likely to cause serious

injury. Quality Standards GB 15763.2, Chinese standard. EN 12150.1,

European standard. EN 12600, European standard. ANSI Z97.1,

American standard. AS/NZS 2208, Australian standard. /* January 22,

2024 19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Ultra/Extra Clear Tempered Glass Low Iron Toughened Glass

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup