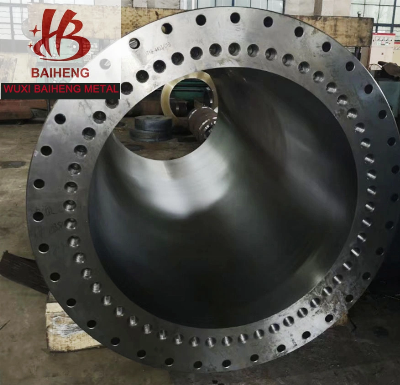

Name : honed tubes, honing pipe, hydraulic cylinder tubes,

pneumatic cylinder tubes, honed pipe, honing tube, seamless honed

steel tube, precision tubes, cold drawn honed tubes, skived tubes,

skived and roller burnished tubes, skived pipes, SRB tube, SRB

pipe, hydraulic SRB tube, hydraulic cylinder skived tubesPopular

standard and steel grade:EN10305-1E355 E235 E410 E470

C45EDIN2391-1ST52 ST45 ST52.3ASTM A519SAE1020 SAE1045

SAE1026GB/T20# 45# 16Mn Q345B Q345D Q345E 42CrMo

27SiMn Application: hydraulic cylinder, pneumatic

cylinder,Jack, cylinder barrelManufacture Method: cold

drawn, cold rolled, Hot rolled+Deep Hole Boring Heat

Treating Method/Delivery

Condition: BKBKSGBKNBKQ+T+C+SR+A+NQ+TCold drawnStress

relievedAnnealedNormalizedQUENCHED + TEMPERED Hydraulic

& pneumatic tube size and

parameters: ManufacturemethodCylinder

ID (mm)Length(m)Straightness(mm/m)Toleranceon IDToleranceon

WTRoughness(μm) Cold drawn40-420≤16M0.2-0.5Depends

on requirement±8%0.8-1.6 Cold

rolled30-100≥14M0.2-0.5Depends onrequirement±5%0.8-1.2cold

drawn-honed40-42014M0.2-0.3H8-H9±8%0.2-0.8Cold

drawn-skived & burnished40-3009M0.2-0.3H8-H9±8%≤0.4Deep

holeboring- honed50-100012M0.2-0.3H8-H9±8%≤0.8Deep holeboring-

skived50-3009M0.2-0.3H8-H9±8%≤0.4 Mechanical

property: Final SupplyConditionCold finished(Hard)(BK)Cold

drawn and stress-relieved (BK+S or + SR)Hardness

HBParametersT.SobN/mm2Elongationδ5%T.SobN/mm2Y.SOsN/mm2Elongationδ5%20#

(A106B, ST45,

E255)>=550>=8>=520>=375>=1217545#(CK45)>=650>=5>=600>=500>=10190Q345B(ST52,

E355)>=640>=5>=600>=520>=1519025Mn>=640>=5>=600>=510>=1519527SiMn>=840>=5>=720>=600>=10210Chemical

Properties: MaterialC%Mn%Si%S%P%20#0.17-0.230.35-0.650.17-0.37≤0.035≤0.035ST45≤0.21≥0.4≤0.35≤0.025≤0.025E255≤0.210.4-1.1≤0.35≤0.025≤0.02545#0.42-0.500.50-0.800.17-0.37≤0.035≤0.035Q345B≤0.20≤1.70≤0.50≤0.035≤0.035E355≤0.22≤1.6≤0.55≤0.025≤0.025ST52≤0.22≤1.6≤0.55≤0.04≤0.0425Mn0.22-0.290.70-1.00.17-0.37≤0.035≤0.03527SiMn0.24-0.321.10-1.401.10-1.40≤0.035≤0.035 Tolerance

on ID:IDTolerance for ID

(μm)H7H8H9H1030+210+330+520+840>30-50+250+390+620+1000>50-80+300+460+740+1200>80-120+

350+

540+870+1400>120-180+400+630+1000+1600>180-250+460+720+1150+1850>250-315+520+810+1400+2100>315-400+570+890+1700+2300 Part

of size list

(ID*OD)40*50 100*127 240*27340*55 110*130 250*26650*60 120*140 250*28050*63 120*145 250*30060*70 125*140 280*32360*73 125*145 280*32563*73 140*165 300*32063*76 140*168 300*35670*80 150*180 320*34070*82 160*184 320*35670*85 160*194 320*37080*90 170*200 350*37080*92 180*210 400*42080*95 200*216 80*100 200*220 90*102 200*232 90*105 200*245 100*114 220*250 100*121 220*273 /*

January 22, 2024 19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Hydraulic Honed Tubes Manufacturer Precision Steel Tube Honing Pipe Cylinder Tubing

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup