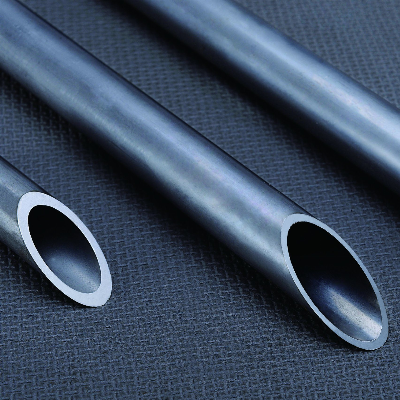

Detailed PhotosStandard: ASTM A519material

: 4130/4140Advantage: Alloy steel round 4140 tubing metric is

normally used for heavy-duty industrial applications. Also referred

to as Chromoly steel, 4140 round tube is known for

strength, resistance to fracturing, abrasion, and impact in

high-stress applications. Description: 4140/42 and 4130

Mechanical Tubing are medium carbon alloy grades, which are

widely used for many general-purpose applications that require high

tensile strength and toughness. The addition of chromium and

molybdenum as alloying elements, combined with heat treatment,

provides the combined advantage of hardness, ductility, and

strength.Delivery Condition:Cold drawn/hard (+C) (BK)Cold

drawn/soft (+LC) (BKW)Cold drawn and stress relieved (+SR)

(BKS)Annealed (+A) (GBK)Normalized (+N) (NBK)Quenched and Tempered

(QT) ApplicationCommercial aircraft, aircraft engine

mountsMilitary aircraftAutomotiveMachine toolsHydraulic toolsAuto

racingAerospaceOil and gas industries - as forged valve bodies and

pumpsAgricultural and defense industries etc Standard Material

Chemical Composition(%) Standard Steel Grade C Si Mn P S Cr

Mo ASTM A519 4130/30CrMo 0.28-0.33 0.15-0.35 0.40-0.60 ≤0.04 ≤0.04

0.8-1.1 0.15-0.25 4140/42CrMo 0.38-0.43 0.15-0.35 0.75-1 ≤0.04

≤0.04 0.8-1.1 0.15-0.25 Mechanical Performance CW SR A N RM

Tensile Strength(Mpa)Min A Elongation(%)Mn RM Tensile

Strength(Mpa)Min A Elongation(%)Mn RM Tensile Strength(Mpa)Min Rel

Yield Strength(Mpa)Min A Elongation(%)Mn RM Tensile

Strength(Mpa)Min Rel Yield Strength(Mpa)Min A Elongation(%)Mn - -

724 10 517 379 30 621 441 20 - - 855 10 552 414 25 855 621 20

Equivalent Material referance: GB TOCT ASTM BS JIS NF DIN 10F

1010 040A10 XC10 10 10 10,101,012 045M10 S10C

XC10 C10,CK10 20 20 1020 050A20 S20C XC18 C22,CK22 45 45 1045

080M46 S45C XC45 C45,CK45 30CrMo 30XM 4130 1717COS110 SCM420 30CD4

42CrMo 4140 708A42 42CD4 42CrMo4

708M40 35CrMo 35XM 4135 708A37 SCM3

35CD4 34CrMo4 Manufacture ProcessCompany Profile Chewit

International Chewit international Located in zhangjiagang city

which is along The Yangtze Golden Channel the junction of River and

Coast Economic Belt. It owns an excellent geographic position, as

it is close to Nanjing city in the north, adjacent to Suzhou and

Wuxi cities in the south, next to Shanghai international city in

the east. Zhangjiagang international port and State highway endow

us a convenient water and land transportation which links us to the

outside world both home and aboard. Chewit International is one

group company with two manufactures one is producing steel forgings

for Marine, Power, Boiler, Ocean, Oil, Petrochemical, Mechanical

and Hydraulic fields and the other is producing precision steel

tubes for automotive industry and hydraulic system and also one

semi-independent company specially for import and export business.

We have a total area of 150000 square meters with the employees

over 200 people. All the products well produced by our mills need

to be double inspected by chewit professional quality controller

and then we will offer our customer the vivid report for the tested

items. Only those products which are inspected well can be allowed

to delivery to our customers. By the means of strict inspection, we

wined a lot of customer for long term business both home and

abroad. We have customers like Danieli, Cedervall,Wartsila,Sannat

mansur, SeaLink, Tata Group, Continental, Iran Khodro and also

other well reputated ones. We adhere to our company tenet Customer

First, Quality formost and always try our best to serve our

customer with our full heart. Packaging & Shipping /*

January 22, 2024 19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Cold Drawn/Draw Precision 10mm 12mm Heat Treatment Chromoly motorcycle Automotive Parts 4130 4140 30CrMo 42CrMo Chrome Moly Alloy Seamless Steel Tube

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup